AQUACULTURE (farming of fish under controlled conditions) is a growth industry striving to satisfy a growing market for food fish. It currently is one of the fastest growing sectors of agriculture in India. Farm-reared fresh fish is increasing in popularity and profitability. Growing public demand for a healthy tasty and affordable food is stimulating the “boom” in this industry. The decline in wild fish populations as a result of overharvest and water pollution has promoted the culture of farm fresh that are grown in contaminant–free waters in indoor tank systems.

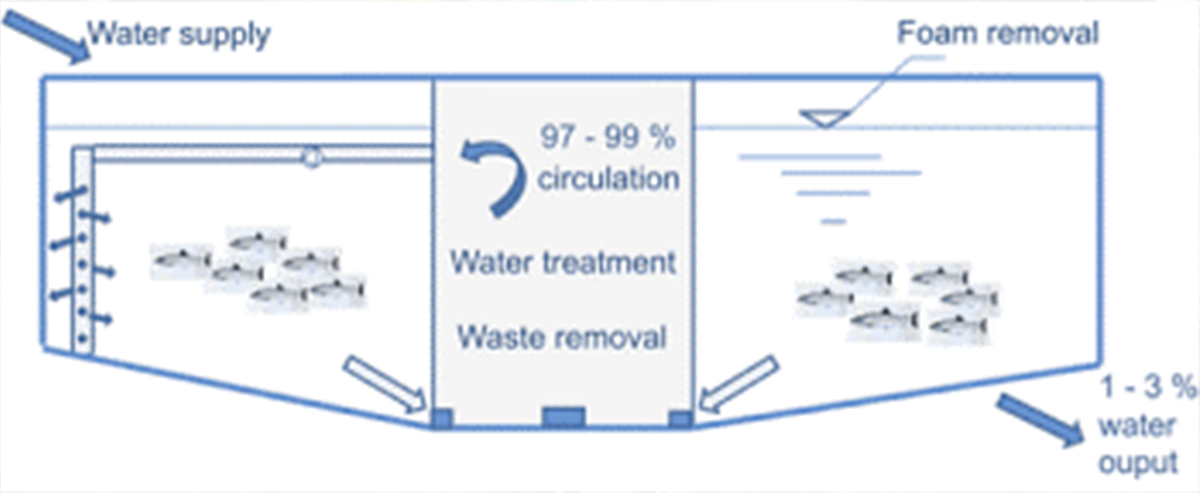

Indoor Recirculating Aquaculture System are land-based fish farms, which allows all year round control and delivery of fish. The system can achieve optimal temperature and optimal stable productions all year around, independent on seasonal variation, location, weather, and environment. Fresh water is added to the tanks frequently to make up for splash out, evaporation and used to flush out waste materials.

They need a continuous supply of clean water at a temperature and dissolved oxygen content that is optimum for growth. The fish must be a fed a nutritionally-complete feed on a daily basis to encourage fast growth and high survival. Other types of filtration and environmental control also necessary to maintain clean water and provide a suitable habitat for fish regularly.

Maintenance of Fish farm

Solid Waste Removal

Removing of solid waste removal process helps to reduce bacteria growth, oxygen demand, and the proliferation of disease. This is done by concentrating and flushing the solids out of the system. The simplest method for removing solids is the creation of settling basin where the relative velocity of the water is slow and particles can settle at the bottom of the tank where they are either flushed out or vacuumed out manually using a siphon. Typical RAS solids removal involves mechanical drum filter where water is run over a rotating drum screen that is periodically cleaned by pressurized spray nozzles, and the resulting slurry is treated or sent down the drain. In order to remove extremely fine particles or colloidal solids a protein fractionator may be used with or without the addition of ozone.

Re-Oxygenating

Fish require oxygen to metabolize food and grow, as do bacteria communities in the bio filter. Re- oxygenating the system water is a crucial part to obtain high production densities. Dissolved oxygen levels can be increased through two methods aeration and oxygenation. In aeration air is pumped through an air stone or similar device that creates small bubbles in the water column, this results in a high surface area where oxygen can dissolve into the water. In general, due to slow gas dissolution rates and the high air pressure needed to create small bubbles this method is considered inefficient and the water is instead oxygenated by pumping in pure oxygen to ensure that during oxygenation all of the oxygen dissolves into the water column. Careful calculation and consideration must be given to the oxygen demand of a system, and that demand must be met with either oxygenation or aeration equipment.

Temperature Control

Temperature is controlled through the use of submerged heaters, heat pumps, chillers, and heat exchangers. All four may be used to keep a system operating at the optimal temperature for maximizing fish production. All fish species have a preferred temperature, above and below which that fish will experience negative health effects and eventually death. Warm water species such as Tilapia and Barramundi prefer 24 °C water or warmer, where as cold water species such as trout and salmon prefer water temperature below 16 °C. Temperature also plays vital role in dissolved oxygen (DO) concentrations.